Products

Products

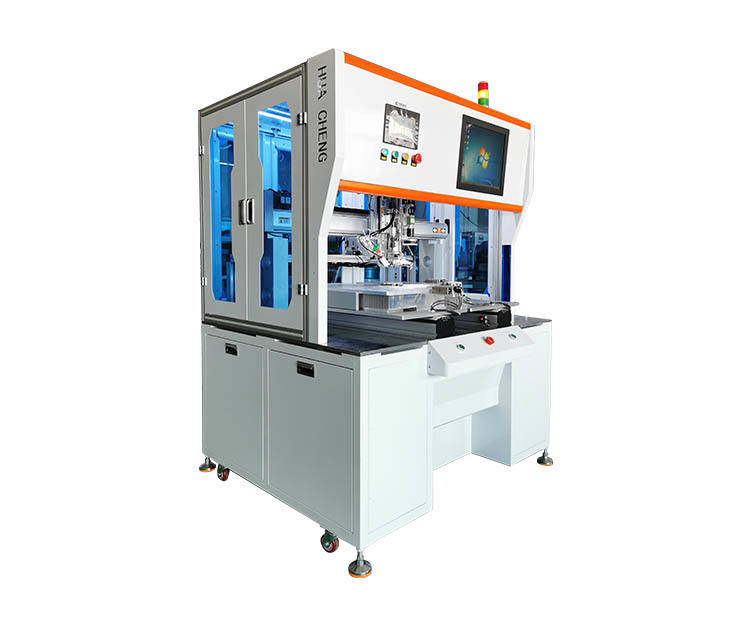

HCF-700 Cross - line CCD vision automatic screw locking machine

1. This equipment belongs to the cross-line lock payment station, which can be equipped with the manufacturer's existing pipeline, do product positioning on the online body, and realize the online lock screw. 2. The equipment is equipped with two sets of visual systems, which are respectively used for the identification of the current incoming product category and the positioning of the screw holes. 3. When camera 1 takes a picture of the current product material, it will automatically switch the locking screws of the machine gun with different locking screws. Example: Camera shot current inflow is No.2 product lock M2.0 screw, side automatic switch M2.0 lock attached gun, carry on locking screw. When the camera shoots the M3.0 screw for product 3, switch to M3.0 lock gun) 4. Camera 2 shoots the hole position of the lock screw, and the device converts the offset position value of the hole position. The exact data is converted to the upper part of the lock position and the lock screw. 5. The biggest advantage of this equipment is that it can identify the current incoming materials, conduct data analysis, and then automatically allocate different processes to be processed. 6. The equipment belongs to non-standard customized internal products, detailed parameters are customized according to different manufacturers!

Message

- Product Description

- Product parameters

- Related Products

-

Brief introduction:

1. This equipment belongs to the cross-line lock payment station, which can be equipped with the manufacturer's existing pipeline, do product positioning on the online body, and realize the online lock screw.

2. The device is equipped with two German IDS cameras, one is to identify the current category of incoming products, the other is to locate the screw hole location.

3. When camera 1 takes a picture of the current product material, it will automatically switch the locking screws of the machine gun with different locking screws. Example: Camera shot current inflow is No.2 product lock M2.0 screw, side automatic switch M2.0 lock attached gun, carry on locking screw. If the camera shoots M3.0 screw for product 3, switch to M3.0 lock gun)

4. Camera 2 shoots the hole position of the lock screw, and the offset position value of the hole position is converted by the device. The exact data is converted above the position of the lock screw.

5. The biggest advantage of this equipment is that it can identify the current incoming materials, conduct data analysis, and then automatically allocate different processes to be processed.

6. The equipment belongs to non-standard customized internal products, detailed parameters are customized according to different manufacturers!

Advantages:

1, can be based on the original line body transformation;

2, the use of visual identification product model;

3. Use visual identification screw to lock the hole position;

4. Multiple screws can be used at the same time for selective locking;

5, can be equipped with intelligent electric batch, realize the screw lock attached data acquisition, such as: torque, number of turns, Angle, etc.;

6, can integrate MES, equipment data and working data upload to the server.

Key words:- Cross - line CCD vision automatic screw locking machine

Message