Products

Products

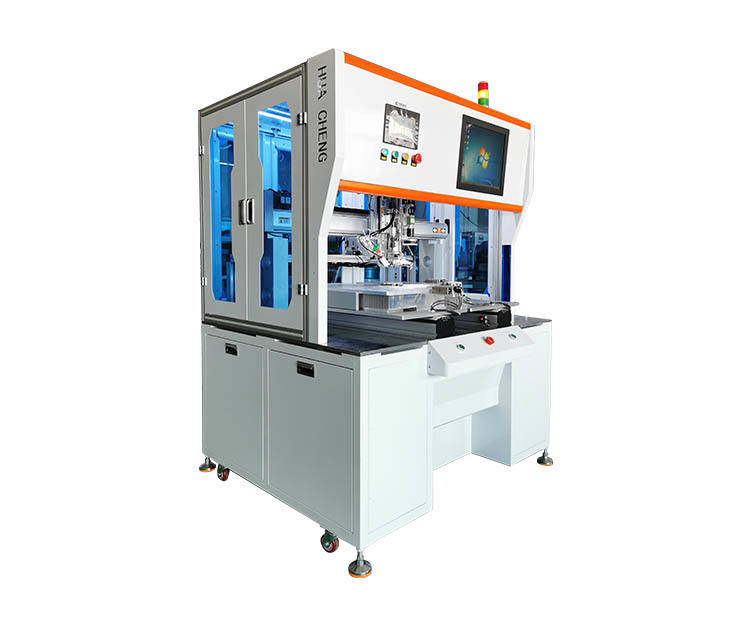

HCD-201 multi - axis automatic screw locking machine

1. Lock multiple screws at the same time, instead of multiple workers, shaft number can be customized according to customer requirements. 2. The device monitors the tightening state from time to time, gives abnormal alarm and prompts the corresponding bad position on the man-machine interface. 3. The electric batch transmits torsion force through the universal transmission shaft, and the hole position can be adjusted according to different products, with strong compatibility.

Message

- Product Description

- Product parameters

- Related Products

-

Product introduction

Features:

1. Lock multiple screws at the same time, instead of multiple workers, shaft number can be customized according to customer requirements.

2. The device monitors the tightening state from time to time, gives abnormal alarm and prompts the corresponding bad position on the man-machine interface.

3. The electric batch transmits torsion force through the universal transmission shaft, and the hole position can be adjusted according to different products, with strong compatibility.

4. The locking mechanism can be adjusted to adapt to slight changes of different product batches.

5. Match the corresponding feeding and tightening methods according to the product characteristics.

6. The machine is simple and practical, easy to learn and easy to use;

Key words:- Automatic screw locking machine equipment

-

Machine construction Gross Weight of Machine: About 200KG Overall Dimensions: Height 1850* Length 800* width 1000 Power Supply: AC 230V 50HZ Power: 0.3KW(calculated by four screws) Gas Consumption: 15m³/hour(on four axes) Rack: Steel mesa, aluminum alloy frame Specification Host Program Control PLC control Man-machine Interface Touch screen Machine Start Split and automatic modes Alarm Alarm lights flashing and buzzers howling Connection Universal Junction & Coupling Assembly Furnish as required Screw Feeder Automatic Feeder Special feed machine for automata Number of Automatic Feeder Set according to the number of device axes Scope Of Application Applicable Product Size: Customized according to customer products Range of Horizontal Adjustment: 25mm-40mm adjustment Vertical Adjustment Range: 15mm adjustment Depth of Screw Locking: 25mm, if deeper need to customize; Minimum Screw Hole Distance: 18mm, unlimited maximum hole spacing Test item Detection of Screw Slip Teeth There are Screw Leakage Lock Detection There are Screw Leakage Detection There are Lock Up the Disposal of Defective Products Alarm light and buzzer warning

Message