Products

Products

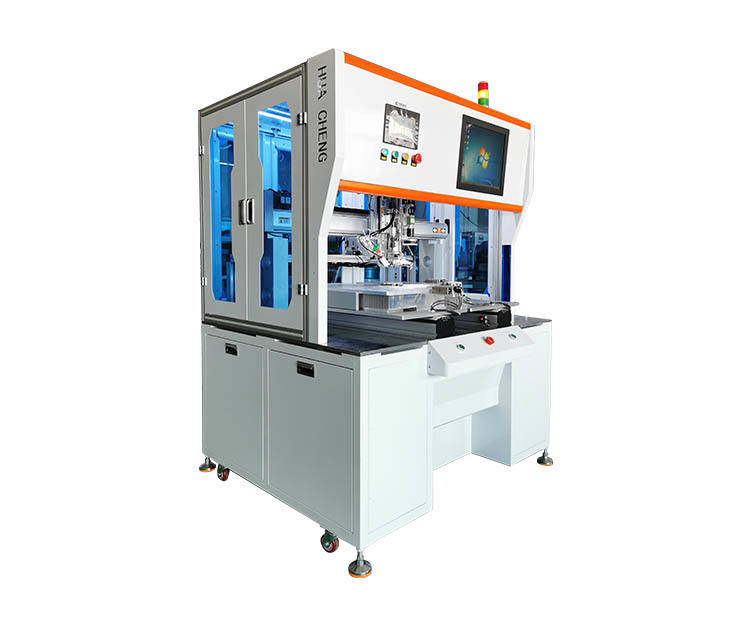

Coordinate desktop automatic screw locking machine HCP-300

Desktop type automatic screw feeding machine is based on the set coordinates, the machine automatically completes the product lock payment. The Z-axis can be equipped with multiple locking mechanisms to achieve simultaneous multi-product locking, greatly improving production efficiency. The model replacement product, as long as by modifying the lock point coordinate parameters, the operation is very simple. In today's era of faster product upgrading, it can greatly save the investment in fixed assets.

Message

- Product Description

- Product parameters

- Related Products

-

Introduction

Desktop type automatic screw feeding machine is based on the set coordinates, the machine automatically completes the product lock payment. The Z-axis can be equipped with multiple locking mechanisms to achieve simultaneous multi-product locking, greatly improving production efficiency. The model replacement product, as long as by modifying the lock point coordinate parameters, the operation is very simple. In today's era of faster product upgrading, it can greatly save the investment in fixed assets.

Advantage

1. Strong versatility. Small size, can cooperate with production line operation, easy to replace products.

2, High efficiency. On the basis of automatic positioning locking can also be installed a number of locking mechanism to achieve the simultaneous locking of multiple products.

3, reduce the labor intensity of workers. Traditional manual screw placement and alignment of screw heads requires a lot of working time and effort.

4,High degree of automation. Simple operation, staff quickly grasp the operation and debugging. One worker can manage several machines at the same time. Save labor.

5,Precise torque. Easy to adjust, to ensure the quality of locking.

6, this model for the blow type automatic screw feeding mode, high efficiency.

Key words:- Coordinate desktop automatic screw locking machine

-

Machine construction Gross weight of machine: About 80KG Overall dimensions: Height 1550* length 650* width 800mm Power supply: AC 230V 50HZ Power: 1000W Ambient temperature: -20~+40 degrees Rack: Steel plate table, aluminum alloy frame Specification Host program control Autonomous special control system Hand-held teaching box Hand-held Instruction Box (Touch screen) Program input Direct coordinate input or computer connection I/O signal 8 INPUT / 8 OUTPUTS Communication Serial port RS232C, computer communication software Speed and accuracy Positioning accuracy X,Y:+/-0.08mm

Z: +/-0.01mmOperating speed 600mm/sec(X-Y) Screw feeder Automatic feeder Put on the workbench Number of automatic feeder According to screw locking mechanism configuration Screw locking tool Electric batch or air batch Optional according to customer requirements Scope of application XY lock payment range: 450*450(MM).Sizes can be customized. Z-axis locking range: Customized according to customer products Test item Detection of screw slip teeth There are Screw leakage lock detection There are Lock up the disposal of defective products Alarm light and buzzer warning

Message