Products

Products

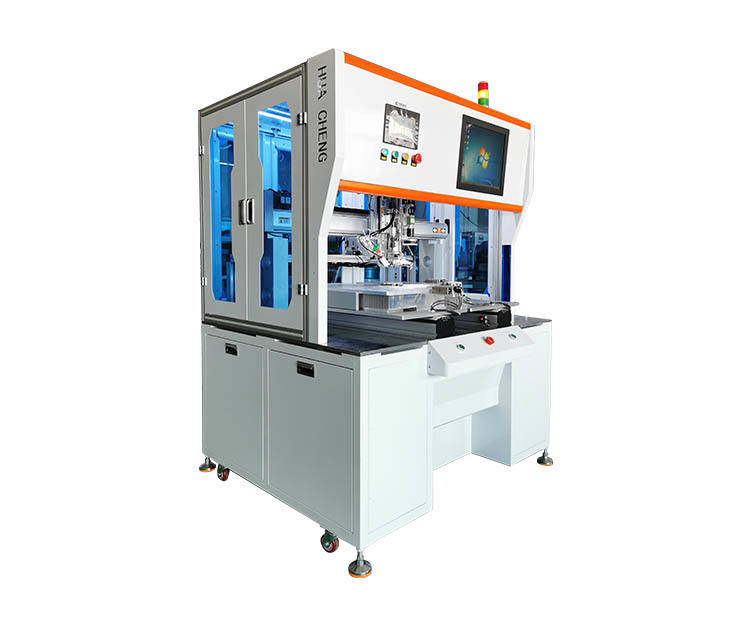

Pneumatic screw feeder

Huacheng screw feeder, it completely subverts the working principle of the traditional screw feeder, abandoned the vibration plate and push, carry forward the advantages of the traditional screw machine, and overcome all the shortcomings, make the screw feeder more portable, safe, stable, fast, low noise, low energy consumption. The key parts are selected high quality alloy steel materials and special heat treatment, the pneumatic and electrical components are selected imported original parts, to ensure that millions of screws zero failure work.

Message

- Product Description

- Product parameters

- Related Products

-

Introduction of equipment advantages

One, can be used for all screws. It takes three simple steps to make it universal. (Other manufacturers can only match one type of screw to one type of this model, we break this tradition and take the lead in the reform. When replacing screws, only need to replace the small module and the batch head can be realized, and the whole replacement process does not need five minutes)

Two, the equipment comes with energy-saving mode. When the equipment is idle for a specific time, the equipment automatically starts the energy-saving mode. This mode can reduce the equipment consumption and reduce the wear between the screws and the guide rail, and ensure the durability of the equipment to the maximum extent. If in use can automatically wake up immediately use without waiting. (Other manufacturers do not have this function, this focus reflects: energy saving, screw and guide wear reduction, increase life, can automatically wake up immediately)

Three, the bin can be opened. When cleaning impurities and replacing screws, it is convenient to open the silo so that screws or impurities can be automatically discharged through the screw outlet. (Other manufacturers of this kind of equipment does not have this function, other manufacturers clean the silo either with magnets, or put the equipment upside down, if the stainless steel screws are more painful).

Definition

Screw feeder needs external gas pipe, mechanism including feeding system, distribution system. All action completion is controlled by the device itself.

Working principle and process

Screw feeder uses turbine feeding to sort the screws on the vibration guide rail, and transferred to the screw distribution system, through the distribution system to distribute the screws and through the gas pipe pressure to the screw to the lock nozzle, by electric or pneumatic screwdriver will lock the screws into the product.

Performance and advantages

Huacheng screw feeder, it completely subverts the working principle of the traditional screw feeder, abandoned the vibration plate and push, carry forward the advantages of the traditional screw machine, and overcome all the shortcomings, make the screw feeder more portable, safe, stable, fast, low noise, low energy consumption. The key parts are selected high quality alloy steel materials and special heat treatment, the pneumatic and electrical components are selected imported original parts, to ensure that millions of screws zero failure work.

Screw feed machine advantages

1, convenient, only one trigger signal can quickly transfer the screw in place.

2, fast, single screw output time is 0.5S.

3, clean, due to the absence of hand to take the screw action, not because of the hand to take the screw produced by the stain on the product secondary pollution and hand sweat stained screws make it more rust.

Key words:- Pneumatic screw feeder

-

Operating voltage

AC220V 50HZ

Working air pressure

2-3KGF/C㎡

Work efficiency

50-70PCS/MIN

Power

19W

Noise

Below 65 decibels

Transport distance

1-4 meters

Screw pocket capacity

2000 standard screws

Overall dimension

260*220*240MM

Fuselage weight

8KG

Message