Products

Products

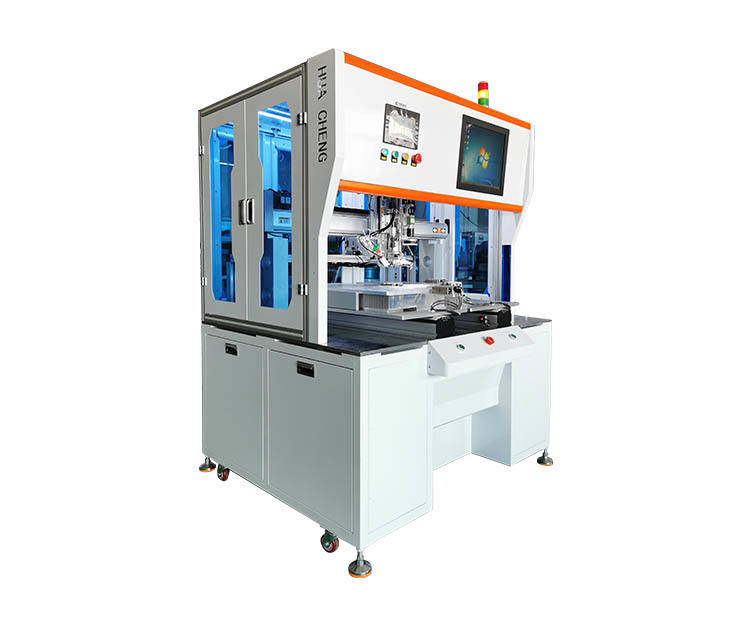

HCQ-650 Automatic rivet nut assembly equipment

HCQ-650 automatic rivet nut assembly equipment is developed for the installation of rivet nuts for pin tie thin-wall products. The device uses CCD vision system to guide servo screw execution module to accurately locate the installation hole of products, and then automatically installs the rivet nuts on the products. During the installation process, the installation torque, installation stroke and installation height are monitored in real time. After the installation is complete, the installation data will be generated and archived in a table.

Message

- Product Description

- Product parameters

- Related Products

-

Product introduction

HCQ-650 automatic rivet nut assembly equipment is developed for the installation of rivet nuts for pin tie thin-wall products. The device uses CCD vision system to guide servo screw execution module to accurately locate the installation hole of products, and then automatically installs the rivet nuts on the products. During the installation process, the installation torque, installation stroke and installation height are monitored in real time. After the installation is complete, the installation data will be generated and archived in a table.

Advantages:

1. Automatic nut feeding system is intelligent, efficient and portable

2. Real-time display and storage of installation depth, installation tension and installation stroke can connect MES system installation data storage and traceability.

3. Self-mounting shaft to solve edge installation problem (optional)

4. Equipped with CCD visual system, accurate positioning of product hole position and accurate positioning of hexagonal hole parallel plane.

5. Suitable for round nuts, hexagon nuts, through holes, non-through holes for installation.

8. It can be customized according to different usage scenarios

Equipment application:

The equipment is widely used in electric vehicle pallets and surrounding, automotive lightweight parts, bullet cars, aerospace, military, energy storage and heat dissipation module, and other application fields

Key words:- Automatic rivet nut assembly equipment

-

Machine construction Gross weight of machine: About 500KG Overall dimensions: About: Height 1850* Length 1200* width 1200 Power supply: AC 230V 50HZ Power: 2300W Ambient temperature: -20~+40 degrees Rack: Square pass welding frame, aluminum alloy frame Specification Host program control PLC+PC Human-computer interaction interface Touch screen Program input Direct coordinate input or computer connection Communication Serial port RS232C, computer communication software Speed and accuracy Positioning accuracy X,Y:+/-0.023mm

Z: +/-0.1mmOperating speed 400mm/sec(X-Y) Send screw sleeve equipment Huacheng Autonomy Huacheng Autonomy Scope of application X range of lock payment: 800mmCan be customized according to customer products Y lock payment range: 600mmCan be customized according to customer products Z-axis locking range: 150mmCan be customized according to customer products Test item Detection of spiral slip teeth There are Screw sleeve leakage lock detection There are Screw sleeve depth monitoring There are Monitoring of mounting torque of screw sleeve There are Handling of defective assembly Alarm light and buzzer warning

Message