Products

Products

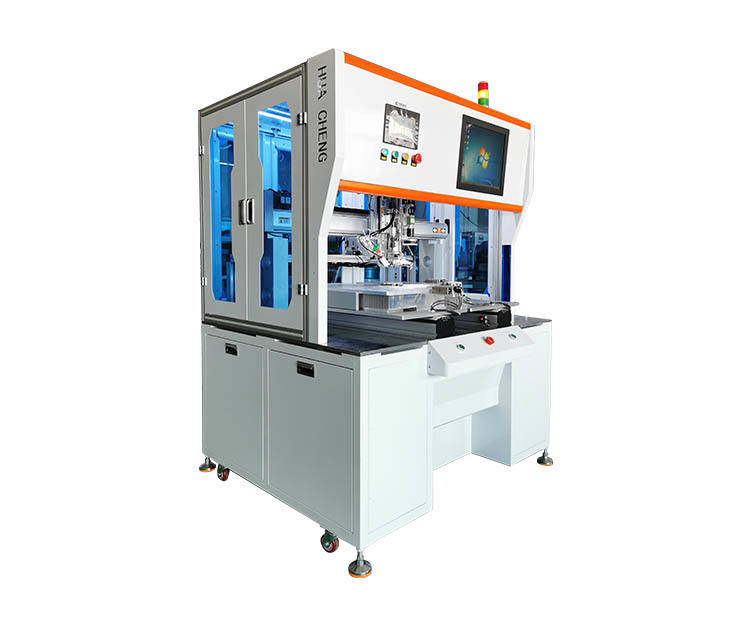

Cf -500 online robot vision lock screw station

Cross-line automatic screw lock machine, belongs to the station type screw lock, can adapt to the automatic production line, realize the screw lock process unattended, assembly line body products, into the current station when the robot self-start vision system, to take pictures of the screw position, processing data to calculate the screw mechanism offset distance, to achieve accurate lock position, but also increase vision, Identify the current flow of products into the station, calculate the lock different screws, this device realizes the future real unattended station.

Message

- Product Description

- Product parameters

- Related Products

-

Brief introduction:

Cross-line automatic screw lock machine, belongs to the station type screw lock, can adapt to the automatic production line, realize the screw lock process unattended, assembly line body products, into the current station when the robot self-start vision system, to take pictures of the screw position, processing data to calculate the screw mechanism offset distance, to achieve accurate lock position, but also increase vision, Identify the current flow of products into the station, calculate the lock different screws, this device realizes the future real unattended station.

Advantages:

1. It can be applied to any assembly line, and there is no need to worry about customized production lines, reducing the cost of customization.

2 automatic visual positioning, do not need to worry about replacing products and not adapt.

3. Rely on visual automatic search need to fill tightening position, high flexibility, strong versatility.

4. As for the screw locking quality, we use servo motor to drive and tighten the screwdriver, which can be equipped with data storage of EMS system to record the locking torque value of each screw.

5. Huacheng Automation makes the robot screw locking process grow eyes, making it more intelligent.

Key words:- Automatic screw locking machine

-

Arm length Full arm length 450 mm, A shaft length 200 mm, B shaft length 250 mm Maximum velocity Axis A + axis B 6670 mm/s, axis Z 1250 mm/s, axis W 1940 mm/s Work space Axis A ±135 °, axis B ±150°, axis Z 200 mm, axis W ±360° Repeated positioning accuracy Axis A + axis B ±0.02, axis Z ±0.01, axis W ±0.01° Maximum load 6kg Weight (body) 33kg Rated voltage 230V a.c. 50/60 Hz Rated power 1kW Lock voltage of motor 24V a.c I/O interface 12-way universal digital input, 7-way universal digital output (expandable)

Message